LEDs compete with traditional lighting sources in a number of ways, including greater energy efficiency, longer lifetime, and smaller size. However, the one drawback that has vexed many lighting designers is cost, which is a key reason why LED manufacturers continue to innovate to improve economies of scale. One of the newest packaging solutions designed to help lower costs is chip-on-board (COB) light source modules, in which the LED chips are in the form of a semiconductor chip that is neither encased nor connected but directly mounted onto a PCB or, more generally, a substrate. This packaging style also provides several related benefits, such as greater design flexibility, better light distribution, and simpler manufacturing processes.

There are other reasons why designers will want to seriously consider COB LEDs for their next design. In a recent report offered by Research and Markets, analysts note that COB LEDs, which are wide-area light emitters (so they also can be used in highway and streetlights), deliver three major benefits: better color mixing, better lighting effect, and low thermal resistance requirements. In addition, because these COB LEDs provide higher power density, more efficient heat dissipation, and require a smaller portion of the board space, they are very suitable for a variety of general lighting applications, according to the firm’s analysts.

Let’s now examine several COB LED examples, including Bridgelux's Vero™, Sharp's Zenigata, and Cree's CXA products, which will show how these devices can simplify lighting designs while saving energy and reducing cost.

Last year, Bridgelux (Livermore, CA) introduced its Vero series of COB LED arrays (Figure 1) with high-performance efficacy: 120 lm/W nominal, 110 lm/W minimum average. This improvement is said to deliver an energy savings of approximately 11 percent compared to the prior product generation. This series is available in four light-emitting surface (LES) configurations and can operate over a broad current range. In addition, the Vero arrays are available with two SDCM (Standard Deviation Color Match) and three SDCM color-control options to deliver high color-control precision and uniform lighting.

Figure 1: The Bridgelux Vero family offers CRI options of 70, 80, 90 and 97 Décor. (The color spectrum for warm white is 3,000 K 80 CRI, 4,000 K 80 CRI for neutral white, and 5,000 K 70 CRI for cool white. Courtesy of Bridgelux).

Higher-precision color control “improves the quality of light by providing greater consistency and uniformity between adjacent light sources," according to Bridgelux. In addition, the Vero series exceeds California Energy Commission R9 requirements for luminaires and lamps.

The 120 lm/W efficacy specification is an average performance across all form-factors based on 3,000 K, 80 CRI configurations driven at nominal currents, according to Bridgelux. However, designers can achieve efficacies up to 140 lm/w when driven at lower currents.

The Vero platform also enables plug-and-play connectivity thanks to an on-board connector port that enables solder-free electrical connections and easy mounting for lighting manufacturers, which helps simplify production processes for them. Benefits include lower cost, faster time-to-market, and lower inventory requirements.

Here are the key specs:

Other benefits include compatibility with a variety of standard drivers (350 mA increments) and optical components, which provides greater design flexibility and more options, contributing to shorter product development cycles, reduced costs, and fewer inventory headaches.

Also delivering simplified designs is the Zenigata COB technology from Sharp Electronics Corp. The Zenigata series of modules is available in three varieties: Mega, Mini, and Petite Zenigata. Sharp's design uses a ceramic substrate instead of metal, which the company said provides "optimal heat dissipation without discoloration." This translates into low color shift with consistent lumen output over time. The uniform LES eases optical design while improving light quality in a variety of applications.

Let’s take a closer look at the Sharp COB modules.

The Mega Zenigata 50 to 80 W modules target high-power lighting applications with its power savings. The high-brightness LEDs are said to eliminate uniformity issues around the use of multiple LEDs in a luminaire. These modules allow the use of just one LED in a fixture, which along with solving uniformity issues, save space. Available in 20 × 24 mm package dimensions, the Mega Zenigata family includes both high- and normal-CRI modules, with minimum performance of 90 CRI and 80 CRI, respectively. These COB LEDs can be used in both indoor and outdoor lighting applications, including architectural illumination, spotlights, downlights, recessed can lights, area and object lighting, and high-intensity lighting.

For mid-sized product applications, Sharp offers the 15 W Mini Zenigata COB family that simplifies the lens and reflector design thanks to its circular 8 mm LES. The Mini Zenigata LEDs, available in a package size of 15 x 12 x 1.6 mm, offer about one-third the surface area of the Mega products, together with a reduction in the emissive area, according to Sharp. Applications include indoor and outdoor lighting, architectural illumination, reading lamps, spotlights, mobile lighting, pendant lights, sign and symbol luminaires, as well as area and object lighting.

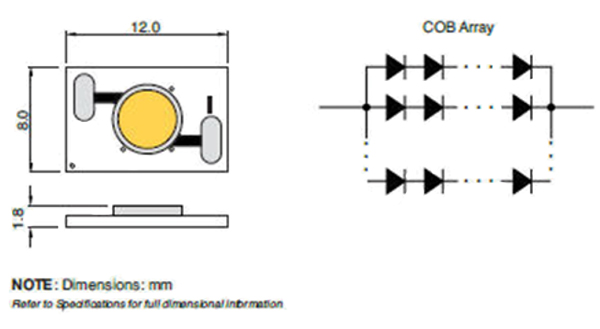

For lower-wattage products, the Petite Zenigata COB LEDs (Figure 2), ranging from 4 to 6 W, are designed for applications that require smaller lenses, including small spot or track light fixtures. These LEDs offer a small package size of 8 x 12 mm and a 4 mm LES. The 9.6 V products allow for the use of a buck DC/DC converter in MR16 lamps (that normally require 12 V), while a higher-voltage 40 V part simplifies the driver design for line voltage GU10 lamps. These LEDs can be used in designs that call for very-small compact lenses, including MR16 replacement lamps, GU10 replacement lamps, small track lights, small spotlights, pendant lights, small reading lights, and small accent lights. The high CRI line (minimum 90 CRI) offers 300 to 395 lumens of brightness.

Figure 2: The Sharp Petite Zenigata COB LEDs offer a small package size of 8 x 12 mm and a 4 mm LES. The 9.6 V products allow for the use of a buck DC/DC converter in MR16 lamps (which normally require 12 V); while a higher-voltage 40 V part simplifies the driver design for line voltage GU10 lamps (Courtesy of Sharp).

Cree Inc. (Durham, NC) recently extended its CXA family with the CXA3070 LED array that delivers more than 11,000 lumens at 85°C. Aimed at simplifying design and lowering total system cost, the high light-output LED arrays deliver up to 134 lumens-per-watt at 85°C and 70-95 CRI options. The LEDs, characterized and binned at 85°C, are available in ANSI White and EasyWhite color temperatures (2,700 K to 5,000 K).

Delivering high lumen output and high efficacy, the CXA3070 LED array is able to deliver system performance of 8000 to more than 10,000 lumens. Translation: it can be used in very-high-lumen output applications such as high bay and ceramic metal-halide replacements.

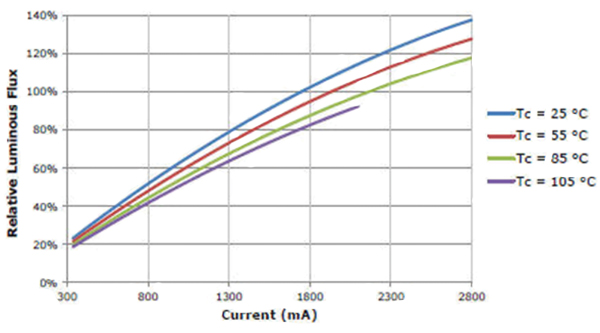

The relative luminous flux values provided by the supplier for the CXA 3070 array (Figure 3 below) are the ratio of measurements of CXA3070 at steady-state operation at the given conditions, divided by flux measured during binning (pulsed measurement at 1,925 mA at TJ = 85°C).

For example, at steady-state operation of TC = 25°C, IF = 1,300 mA, the relative luminous flux ratio is 80 percent as shown in the chart. A CXA3070 LED that measures 8,500 lm during binning will deliver 6,800 lm (8,500 * 0.8) at steady-state operation of TC = 25°C, IF = 1,300 mA.

Figure 3: The relative luminous flux values are based on the ratio of measurements of the CXA3070 in steady-state operation at the given conditions, divided by flux measured during binning (pulsed measurement at 1,925 mA at TJ = 85°C) (Courtesy of Cree).

Key specs for the Cree CXA3070 array include:

In summary, cost is always a big issue for lighting designers. However, as the average selling prices for LEDs decrease, the adoption of COB LEDs will continue to increase as designers find these devices offer the potential to offer higher energy savings, greater design flexibility, as well as better light distribution that will benefit both lighting system manufacturers and end users.